Viewing options: download a PDF or watch the 6 minute video below introducing Eric and his production system.

Case Study Profile

Location: Genesee, Idaho

Precipitation: 22 inches average

Cropping system: 3-year rotation of winter wheat, pulses (including lentils and several types of garbanzos), and spring grain (wheat or barley); experimental spring canola rotation

Eric Odberg is a fourth generation farmer who practices no-till management and was an early adopter of variable rate nitrogen (VRN) application in the dryland production region of the Pacific Northwest.

Throughout their years of farming, Odberg and his wife Malia have been motivated by the desire to pass along an environmentally and economically sustainable operation to their three sons. They currently farm about 2200 acres in a 3-year rotation of winter wheat, pulses, and spring grain. “I’m fourth generation, and hope to be able to hand it to the fifth generation. Having a sustainable farm is an important part of that. I want to have land to be able to farm, but also want it to be profitable.”

Odberg sees VRN as just one strategy in his ongoing efforts to keep his operation profitable and to provide good stewardship for his land. “You’re applying less nitrogen out there, which is better for the environment. You’re not putting on excess, which would just go into the groundwater and into our rivers and streams. The direct seeding also helps with that, reducing the loss of topsoil and nutrients that are going into our waterways. So I really see them [working] hand in hand, with direct seeding being the foundation.”

Above: Genesee, Idaho is in the annual cropping zone.

Above: Genesee, Idaho is in the annual cropping zone.

Above: Odberg views direct seeding as the foundation required for applying nitrogen at a variable rate among his cereal crops. View Odberg's video for the full picture of his production process and farm.

Figure 1. As a no-till farmer, Eric Odberg seeds directly into residues such as his previous garbanzo crop.

Figure 1. As a no-till farmer, Eric Odberg seeds directly into residues such as his previous garbanzo crop.

Getting Started with Variable Rate N

Odberg’s journey to VRN began long before he actually tried it, starting with his transition to direct seeding in 2000, a few years after he took over the management of his family’s farm (Figure 1). “I had a couple of big erosion events when I first started farming, and I could see that wasn’t going to be sustainable and that we needed to change. And direct seeding was a good solution to that.” Direct seeding led Odberg to adopt a series of additional new practices, including diversifying his rotations, growing multiple classes of wheat, and applying nitrogen (N) at variable rates.

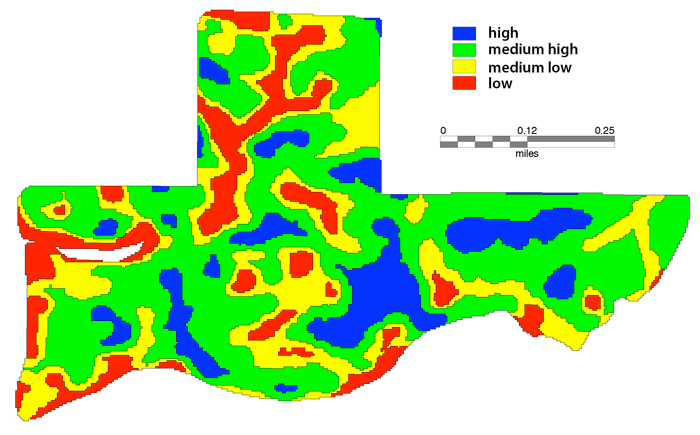

Odberg first began experimenting with precision agriculture in 2005, when he purchased an Exactrix anhydrous fertilizer delivery system for his no-till drill, seeking to improve the evenness of his N applications and reduce overall N use (see sidebar, “Odberg’s Equipment”). By keeping the pressure higher than most other application systems, the Exactrix system maintains anhydrous ammonia as a liquid as it is injected into the soil, reducing gaseous losses of ammonia compared to many other systems. As Odberg looked for strategies that would further reduce N fertilizer use, Guy Swanson, a mentor and the owner of Exactrix Global Systems, suggested that he try VRN application. Instead of applying N at the same rate across the field, based on average yields, he could probably reduce N applications on his hilltops, where the soil was thinner and production was lower (Figure 2).

Figure 2. The rolling landscape of the Palouse has led to important differences in soils at different landscape positions. For example, in many places, higher erosion rates on hilltops has led to thinner soils and lower production potential compared to lower areas. On the hillside in the back of this photo, you can see different rates of crop drying. This is related to variation in soil factors that influence how much water the soils hold.

Figure 2. The rolling landscape of the Palouse has led to important differences in soils at different landscape positions. For example, in many places, higher erosion rates on hilltops has led to thinner soils and lower production potential compared to lower areas. On the hillside in the back of this photo, you can see different rates of crop drying. This is related to variation in soil factors that influence how much water the soils hold.

While this made sense, Odberg wanted to see it for himself—and participation in the USDA-NRCS Conservation Security Program (CSP) gave him that chance. He used funds from the environmental enhancement program to purchase a yield monitor. During his 2006 harvest, he saw for himself—and was surprised—how much yields varied across his fields: from less than 50 bushels per acre (bu/ac) on hilltops, to over 150 bu/ac in the draw bottoms. This convinced Odberg that VRN applications would be beneficial.

Odberg’s Precision Agriculture System

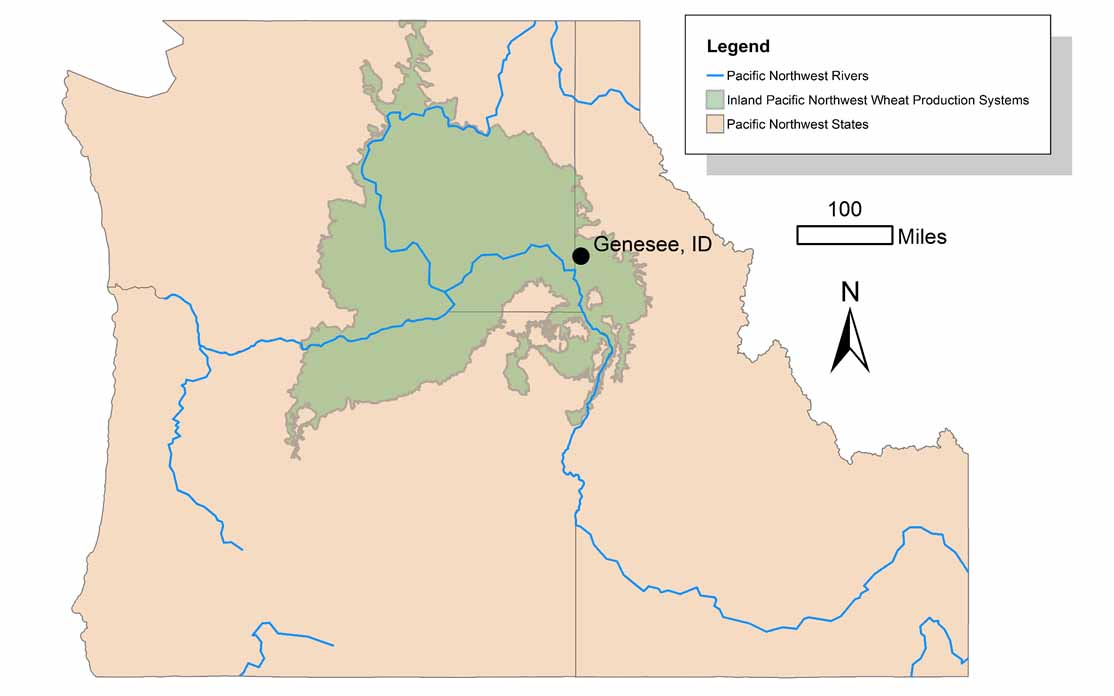

Figure 3. Fertilizer application map developed for one of Odberg's fields showing his four zones.

Figure 3. Fertilizer application map developed for one of Odberg's fields showing his four zones.

The prescription maps Odberg uses for N applications were developed from his yield maps with the help of a precision agriculture specialist, Dave Barton (Figure 3). Odberg has found that yield patterns are fairly stable from year to year, so his zones are likewise consistent. Working with a consultant has been a key part of his strategy. Without established guidelines that dictate how to translate the yield maps into fertilizer prescription zones, having the support of someone with practical experience in other situations was helpful, particularly when he was first learning.

Odberg’s system includes two separate controllers: one to vary fertilizer applications as described by his application map as he drives across the field, and another to auto-steer. In 2013, he updated his controller so that he can apply multiple products at variable rates—a feature he is using to vary the rates of seed and nutrients other than N. Odberg typically uses four zones for N application, as shown in Table 1. The lowest yielding areas receive 50–55 lbs of N per acre, two middle zones receive 80–90 lbs and 100–110 lbs, and the highest producing areas receive 120–130 lbs.

| Zone | Application Rate (lbs per acre) |

Yield (bu per acre) |

| Low | 50-55 | 35-55 |

| Medium 1 | 80-90 | 80-90 |

| Medium 2 | 100-110 | 100-110 |

| High | 120-130 | 130-150 |

To fine-tune his decisions about how much N to add, Odberg takes composite soil samples before planting a field (in fall for fall-planted crops, in spring for spring-planted crops). He previously tried sampling management zones separately, but he found it difficult to make sense of the results he was getting. So he went back to sampling by field, and uses that information to adjust his application rates across the board.

Since implementing variable rate technologies, Odberg has reduced his overall N use by 15%, with no impact on yields. Of his savings, about 7% comes from using auto-steer, which reduces overlap in N applications (see sidebar, “Fertilizer Cost Savings Using Precision Ag Tools”). An additional 8% savings comes from the use of variable zones. The savings, according to Odberg, is enough to benefit his bottom line, and he is optimistic that there is still room for future improvement.

Learning, Experimenting, and Adapting

Especially when he was first transitioning to conservation tillage, mentors were an essential resource. For example, when he first used direct seeding, Odberg asked many questions of his neighbor Russ Zenner. He also interacted with other experienced direct seed farmers with his participation in the Pacific Northwest Direct Seed Association group, which sponsors hosted breakfast meetings for growers during the winter months. Funding through programs such as USDA NRCS’s Environmental Quality Incentives Program (EQIP) and the Conservation Security Program (CSP) have also provided helpful financial resources that made it easier to explore new practices.

Odberg has also learned by jumping in and doing things on his own. About variable rate technology, he said, “It just seemed very obvious to me, and that’s why I just went into it head-first, and really haven’t looked back. But it is a leap of faith. And I don’t have all the answers.” Over time he has built a base of knowledge that he can draw on to solve problems as they arise, both through learning from others and his own experimentation.

Odberg sees variable rate as just one strategy in his ongoing efforts to improve his growing practices. He continually evaluates what he does, identifies areas for improvement, and talks with other growers about their strategies. He also keeps up with the latest publications to get ideas from other regions that he can adapt for use here. Lastly, participating in research studies has helped Odberg stay on top of cutting-edge techniques. Currently, he is a grower-cooperator in Washington State University’s Site-Specific Climate Friendly Farming Project (see sidebar, “Research on Improving Management of Precision Agriculture”). Beyond contributing to the development of new knowledge, he hopes he will be able to evaluate and improve the N application zones he’s using and learn more about his soil compaction, soil quality, and nutrient management.

Odberg's Equipment

Figure 4. Odberg's drill and fertilizer delivery system.

Figure 4. Odberg's drill and fertilizer delivery system.

Figure 5. Exapta (or Thompson) closing wheel (spiked wheels on left) and Keaton seed firmers (center).

Figure 5. Exapta (or Thompson) closing wheel (spiked wheels on left) and Keaton seed firmers (center).

Figure 6. Exatrix system, with Corking ammonia pump to increase ammonia pressure, a mass flow meter with digital readout, and a regulator valve.

Figure 6. Exatrix system, with Corking ammonia pump to increase ammonia pressure, a mass flow meter with digital readout, and a regulator valve.

Figure 7. The system also uses an ammonia manifold and accumulator to further increase the ammonia pressure.

Figure 7. The system also uses an ammonia manifold and accumulator to further increase the ammonia pressure.

Figure 8. Trimble FMX controller (screen on R) can independently control the rate of up to four products. Raven Envizio Pro (smaller screen on L) carries out auto steer and provides guidance.

Figure 8. Trimble FMX controller (screen on R) can independently control the rate of up to four products. Raven Envizio Pro (smaller screen on L) carries out auto steer and provides guidance.

Drill and Fertilizer Application: Odberg direct seeds with a John Deere 1895 no-till drill, adapted for use with an Exactrix liquid anhydrous fertilizer delivery system (Figure 4). Odberg has made several modifications to his drill to improve performance over the years. After breaking too many discs and hubs in hard, dry conditions, he changed to bigger, heavier duty hubs for the single discs on his drill. To ensure consistent seed depth and good contact with the soil, he uses Keaton seed firmers, which have given him better results than firming wheels (Figure 5). He also uses Exapta (or Thompson) closing wheels. He’s found that the spiked wheels are better for closing the seed trenches, especially under wetter conditions.

Many anhydrous ammonia application systems reduce pressure, whereas the Exactrix system increases and regulates the pressure using a pump, manifold, and accumulator (Figures 6 and 7). This keeps the ammonia in liquid form (as opposed to a gas) until it is applied to the ground. Before he purchased this system eight years ago, Odberg struggled with high gaseous losses of ammonia N, especially under hard, dry conditions and during cold, wet spring weather. He also found that the cold ammonia gas in his old system was causing the discs to freeze up, resulting in plugging problems with his drill.

Odberg has found that the Exactrix system works well for applying N at variable rates. The ammonia manifold and accumulator (Figure 7) allow the system to easily vary the rate of application. Odberg finds he can vary the rate from 50 to 120 lbs of N per acre without changing orifices.

Odberg has also made several modifications to his anhydrous liquid fertilizer delivery system. For example, having the closing wheel right behind the outlet for the liquid anhydrous ammonia is key. As the anhydrous ammonia leaves the pressurized system, it tends to convert to gas, and closing the soil over it quickly reduces atmospheric exposure and losses.

Variable Rate Application Controller: To vary the rate of N as he goes, Odberg uses a Trimble FmX variable rate controller (Figure 8). While his old controller was only able to vary the rate of one product, the newer Trimble system he purchased in 2013 allows him to vary up to 4 or 5 products at a time. For auto-steer and guidance, he uses a Raven Envizo Pro.

Pros of Odberg’s System: Odberg feels the Exactrix system allows for reduced N rates with better distribution and placement of fertilizer. It works well with variable rate fertilizer applications because it is very responsive.

Using two controllers rather than one has worked better with his setup, giving him good results.

Cons of Odberg’s System: Because the system is complicated and requires a skilled operator, Odberg needs to be the one to operate the machinery.

Benefits

Odberg sees many benefits to his production practices. Direct seeding and diversified rotations are at the heart of his system, working together to increase organic matter, reduce compaction, and improve soil quality. His overall weed issues also seem to be relatively manageable, with the exception of a growing problem with rattail fescue (see New Directions). Though it would be possible to use variable rate technology in a conventionally tilled field, Odberg finds that these technologies work together to reduce the loss of topsoil and N.

I think there is a great environmental gain with variable rate. You’re putting less nutrients out there. It’s not a lot less, but that’s just less that is going into our environment. And it’s using less of that petroleum-based resource that we’re not going to have forever. So it’s a win as far as cost savings for me as a producer, and it’s a win for the planet and general populace, with less nitrogen going into our environment, whether it’s in the atmosphere or our waterways.

Odberg also sees a practical benefit from precision N application. He sees a lot less downed or lodged wheat than he used to, which he attributes to fewer areas receiving too much N. This makes his harvest go more smoothly and makes his direct seeding easier, since the residue is standing rather than lying down.

Challenges

For Odberg, the biggest challenge with precision N application has been the expense associated with the technology. High equipment costs make purchasing decisions critical. Early on, he purchased a controller that would only apply one product at a variable rate, rather than the multiple products it advertised. This limited him to varying the rate of N only.

Managing the technology has also been a challenge. Odberg sees himself as having a certain level of comfort with technology, but he doesn’t see himself as an expert. Using the services of a precision agriculture specialist has made all the difference, but it has also made him dependent on that person. The precision agriculture specialist he had been working with recently moved to another job, and since then Odberg has been exploring other options, including doing more of it himself and using the services of a consultant associated with a fertilizer supply company. He hasn’t yet settled on a consistent strategy, but he is confident that because the precision agriculture field is growing so rapidly, he will be able to find someone soon who can fill the gap.

Despite the challenges, Odberg thinks using variable rate technology has been worth it. “Of all the production areas in the United States, we probably have the greatest variation out there because of our hills,” he says. “The Palouse is just screaming for this technology, and I think everyone will probably be doing it eventually.”

Fertilizer Cost Savings Using Precision Ag Tools

In Odberg’s experience, precision agriculture allows him to save about 15% per acre on his anhydrous N costs. Of this, about 7% results from his use of auto-steer, which reduces overlap on each pass as well as on the field borders. Variable rate application saves him about another 8%. For example, assuming an application rate of 90 lbs per acre of anhydrous N, he would save about 6.3 lbs of N with auto-steer and about 7.2 lbs from VRN application. Assuming an anhydrous price of $0.63 per pound, auto-steer saves $3.97 per acre and VRN saves $4.54 per acre, for a total savings of $8.51 per acre. Over several thousand acres, the savings are substantial and will help pay for precision agriculture upgrades. Reducing N runoff and leaching with variable rate application are additional benefits.

| Nitrogen reduction (%) | Nitrogen reduction (lb) | Price, anhydrous N ($/lb) | Savings per acre ($/ac) | |

| Auto-steer | 7% | 6.3 | .63 | $3.97 |

| Variable rate | 8% | 7.2 | .63 | $4.54 |

| Total | 15% | 13.5 | .63 | $8.51 |

Managing Risk

While farming is never risk-free, Odberg feels his production strategies combine to reduce his overall risk. His production risk is lowered and his system is more resilient due to his use of direct seeding and diverse rotations. Meanwhile, using precision N technology reduces his reliance on fertilizer, contributing to decreased risk from fluctuations in input prices. “Variable rate is just another component…it’s not big, but it’s [part of] a tool belt,” he says. At the same time, Odberg acknowledges that it’s possible that variable rate technology could result in overall yield reductions—but he has not yet experienced this.

Odberg made several decisions that helped offset the risk of adopting a new, complex, and expensive technology. He was able to reduce equipment costs by participating in cost-share programs when he was getting started, and utilizing the services of a precision agriculture specialist helped him learn the technology.

Through diversification, Odberg has also tried to lower his marketing risk. By growing more crops and several different classes of wheat, he is less dependent on the prices of any one particular crop. Meanwhile, he also markets about a quarter of his wheat through Shepherd’s Grain, receiving a fixed price. The price may be higher or lower than the price he gets through commodity markets, but overall it makes his income less vulnerable to the ups and downs of those markets. As a side benefit, when his family takes a trip to Seattle or Portland, they like to visit a bakery or restaurant that uses Shepherd’s Grain wheat. They enjoy the chance to connect with the end result of their work, by talking with the baker and eating products made with the wheat they grew.

New Directions

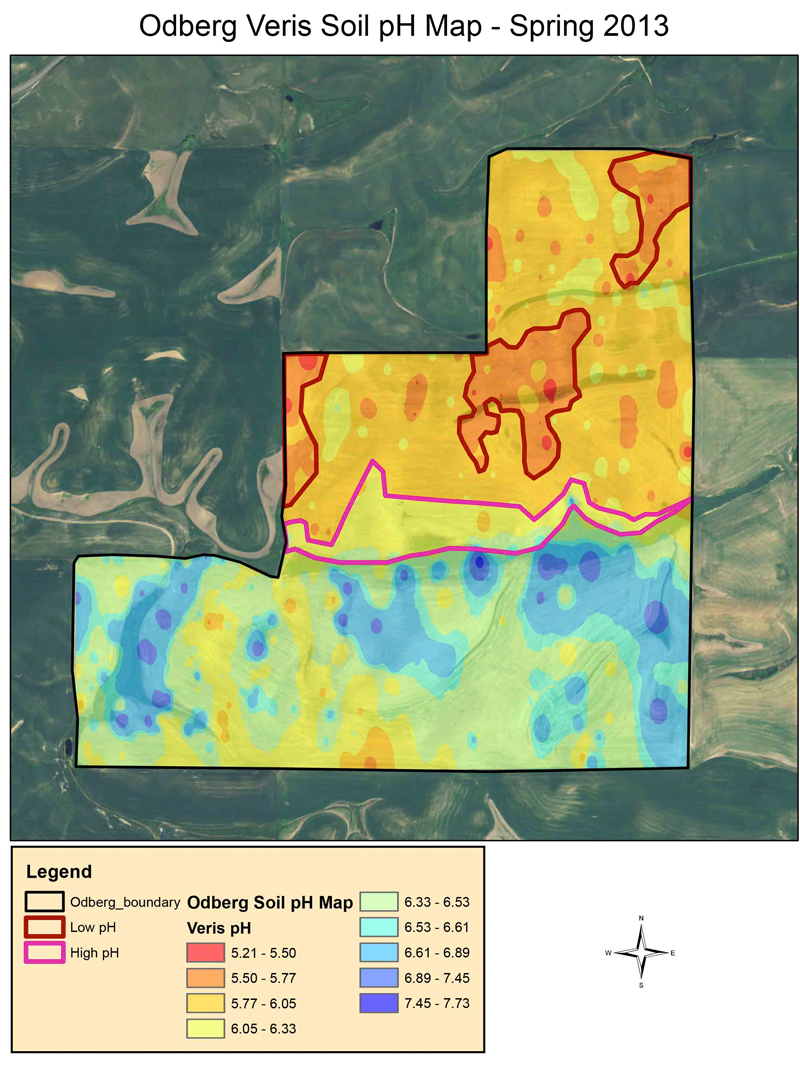

Figure 9. A pH map for one of Odberg's fields generated as part of the study on variable rate liming carried out by the Latah Soil and Water Conservation District (and funded by an Idaho Natural Resources Conservation Service, Conservation Innovation Grant). Colors show pH as indicated by Veris pH detector; these pH maps and lime requirement tests were used to guide lime application rate decisions. (Map courtesy of Tabitha Brown.)

Figure 9. A pH map for one of Odberg's fields generated as part of the study on variable rate liming carried out by the Latah Soil and Water Conservation District (and funded by an Idaho Natural Resources Conservation Service, Conservation Innovation Grant). Colors show pH as indicated by Veris pH detector; these pH maps and lime requirement tests were used to guide lime application rate decisions. (Map courtesy of Tabitha Brown.)

Odberg has been working to improve his N prescription zone maps over time and to map new fields he is farming. To do this, he has been experimenting with supplementing, or even replacing, the information from his yield monitors with infrared crop canopy images taken during the growing season. So far, Odberg has found that these images correlate well with his yield monitor data. This has increased his confidence that he can use the infrared photos when his yield maps are incomplete. (Of their two combines, only one has a yield monitor.)

Over time, he is also hoping to fine-tune his N application rates. For example, he wonders whether raising his N rates on his already high-yielding areas might raise overall yields.

Odberg is starting to explore the impacts of applying other products at variable rates. In 2013, he began participating in a study on variable rate lime applications led by the Latah Soil and Water Conservation District. And because lime is an expensive product, he feels this has good potential to be cost-effective. On his own, he has also begun to apply potassium and phosphorus at variable rates, with higher rates on eroded hilltops where he’s discovered these nutrients are deficient. Though he is just beginning to try this out, he’s eager to see what results he finds.

Odberg is also excited to begin experimenting with applying seed at variable rates. “It’s all related to water and soil depth. I think we have been over-seeding our south slopes and hilltops,” he says. “[In those locations], we just don’t have the water-holding capacity, so we really don’t need so many plants out there. Maybe we have been under-seeding our north slopes and draw bottoms, where we have more available water longer in the growing season.” And with seed becoming more expensive, he thinks the cost savings could be important.

Beyond precision farming, Odberg continues to try out new production practices. He is currently incorporating Roundup Ready canola into his rotation of winter wheat, pulses, and spring grains, which adds diversity as well as new weed control options. Among other things, he is hoping this may help reduce a developing problem with rattail fescue in some fields.

He would also like to experiment with cover cropping, though he anticipates significant adaptation will be needed before it can work in the dryland Pacific Northwest.

Research on improving management of precision agriculture

By David Brown and Erin Brooks

Scientists at Washington State University, University of Idaho, and the United States Department of Agriculture – Agricultural Research Service are working to understand how growing conditions vary within fields at different locations in the Palouse. The Site-Specific Climate-Friendly Farming (SCF) project is improving understanding of variations in physical, chemical, and biological processes, and translating this into information that farmers can use to implement and improve precision management.

To better understand these processes under real management conditions, the SCF project established four research areas in small catchments on grower-collaborator fields. Sites include Eric Odberg’s farm near Genesee, ID, as well as farms near Colfax, WA; Leland, ID; and Troy, ID. The sites span a range of climatic, soil, and topographic conditions across the Palouse.

At each site, scientific instruments have been installed to capture a range of measurements. At twelve carefully selected locations within each site, soil moisture and temperature are measured hourly at five depths to 60 inches (150 cm). Grain yield and protein, crop biomass, carbon, nitrogen, and nitrogen mineralization rates are also being measured. Hydrologic flumes monitor water and nitrogen outputs. Weather information is collected with weather stations.

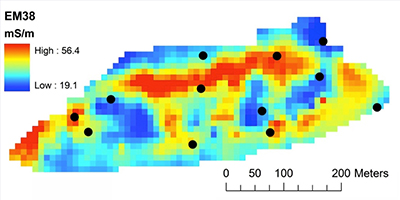

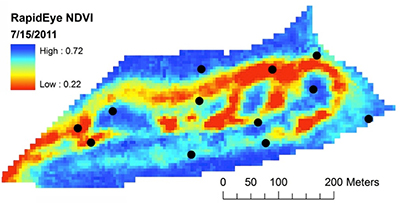

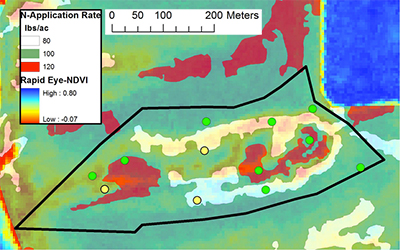

The project relies heavily on both direct measurement of the spatial variability of soil and hydrologic properties and on the development and refinement of remote and field-based sensing technologies that can be used for rapid and inexpensive characterization of variability within fields. Soils are mapped across the catchment using cutting-edge soil sensing instruments, and important crop parameters (e.g. biomass, nitrogen content, water stress) are mapped repeatedly during the growing season using RapidEye satellite infrared imagery.

While this research is ongoing, preliminary results suggest that lower yielding areas of Eric Odberg’s fields have high clay content or have a shallow clay layer below the soil surface. Soil moisture data indicates the these shallow soils are very “flashy,” wetting up and drying quickly. Overall, the prescription maps developed by Odberg and his precision agriculture specialist Dave Barton indicate a strong understanding of variability within Odberg’s fields. Drying patterns and crop yields matched well with fertilizer application rates, suggesting that nitrate losses were minimized by variable rate application of fertilizer.

Soil electrical conductivity measurements (relatively easy to acquire) document variations in clay and moisture content of the soil across the field.

Soil electrical conductivity measurements (relatively easy to acquire) document variations in clay and moisture content of the soil across the field.

RapidEye infrared imagery indicating drying patterns. Red areas are dry, blue areas are actively growing. Notice that these patterns match well with the soil electrical conductivity measurements.

RapidEye infrared imagery indicating drying patterns. Red areas are dry, blue areas are actively growing. Notice that these patterns match well with the soil electrical conductivity measurements.

Fertilizer prescription maps draped over the RapidEye imagery. Notice the close correlation between zonal boundaries and drying patterns.

Fertilizer prescription maps draped over the RapidEye imagery. Notice the close correlation between zonal boundaries and drying patterns.

Looking Forward

When he looks forward, Odberg thinks that farming is going "back to the future." While old practices such as cover cropping are getting a new look, new technologies such as precision agriculture and improved crop varieties are also providing new options.

Odberg hopes precision agriculture will create more opportunities for future generations to be involved in agriculture. He is also hopeful that these new technologies will make farming more appealing to his sons, since sitting on a tractor is combined with sophisticated tools that make it more interesting and challenging. He thinks these tools will be increasingly integral in the future, though he cautions that these tools won’t replace the need to be connected to the land.

Growers in the inland Pacific Northwest are lucky, Odberg says. "We're very blessed here in the Pacific Northwest to have a fairly consistent climate, I think." But over the years he has also noticed more weather extremes like longer dry or wet periods. His sense is that these extremes are here to stay, but that given the overall resiliency of his no-till system, he'll be able to manage around them. In some cases, changes in his equipment have been key to managing new conditions. For example, he has adapted his no-till drill to seed through hard, dry soils during extended dry periods in the fall. He also thinks that growing new varieties, such as the early maturing types, will be important in the future.

Odberg's Advice for Others

Take the plunge, but have realistic expectations. "Don't get hung up on the details of how much you should be reducing and how much you should be changing things. Just get started doing it.... But don't make drastic changes. Have realistic expectations that you're not going to have huge savings, but you’re going to have savings."

There are more equipment options now than ever before, but purchasing decisions are still critical. The number of equipment options has grown since Odberg first started. The technology has also generally been better tested and developed, in some cases in the terrain of the Inland Northwest. However, even with these ongoing technology developments, Odberg cautions, "When you are deciding to update to a new system that has the potential to do more, you want to make sure that it can actually do what you want it to do."

Don't be intimidated by the technology. Odberg doesn't consider himself to be particularly tech-savvy, but having a precision agriculture specialist and other knowledgeable resource people to turn to has allowed him to successfully adopt variable rate N application. He thinks that some growers think they need to be more knowledgeable about technology than is really required.